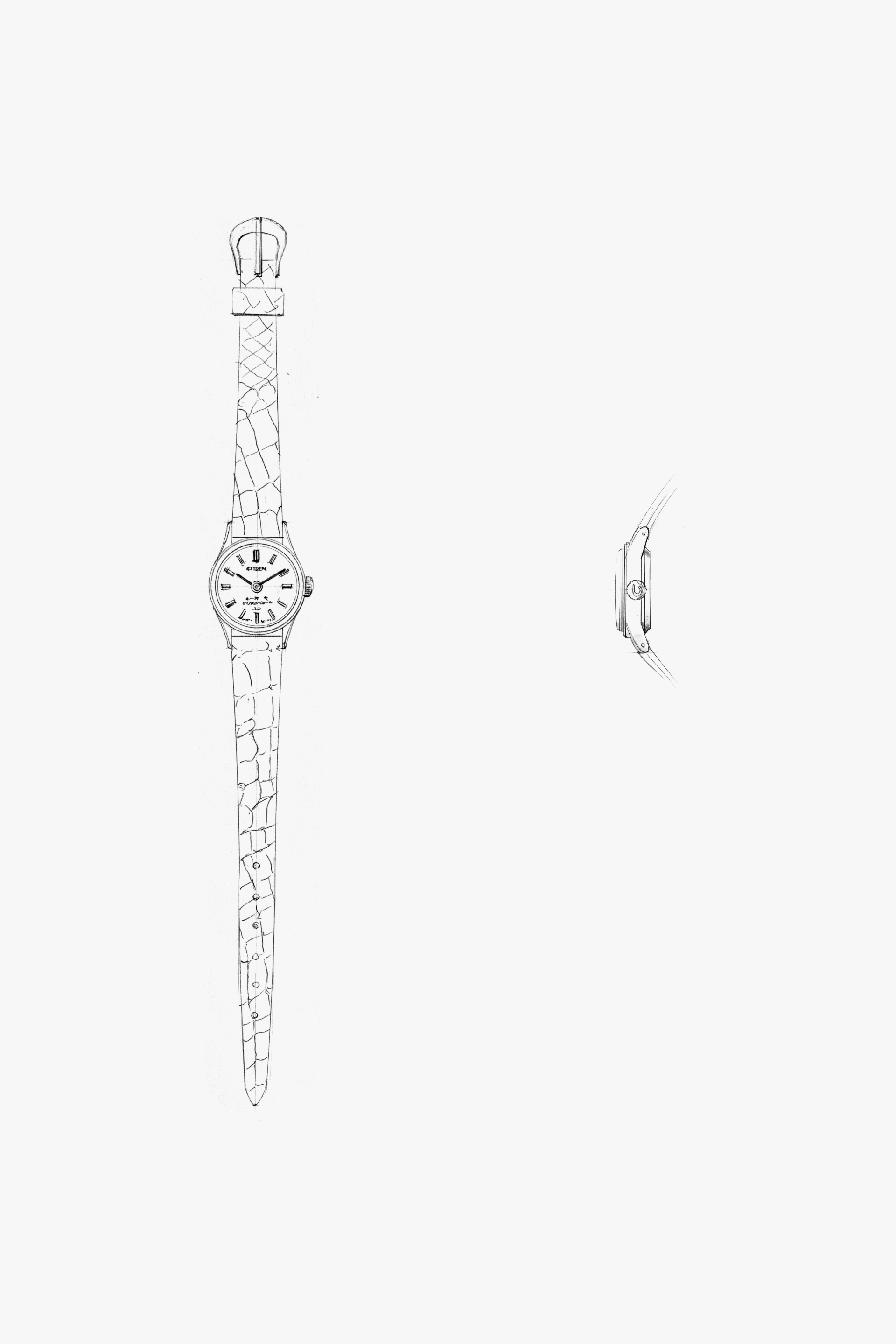

One of the luxury line models of the time. Attention to detail, such as the indexes, gives this watch a sense of luxury.

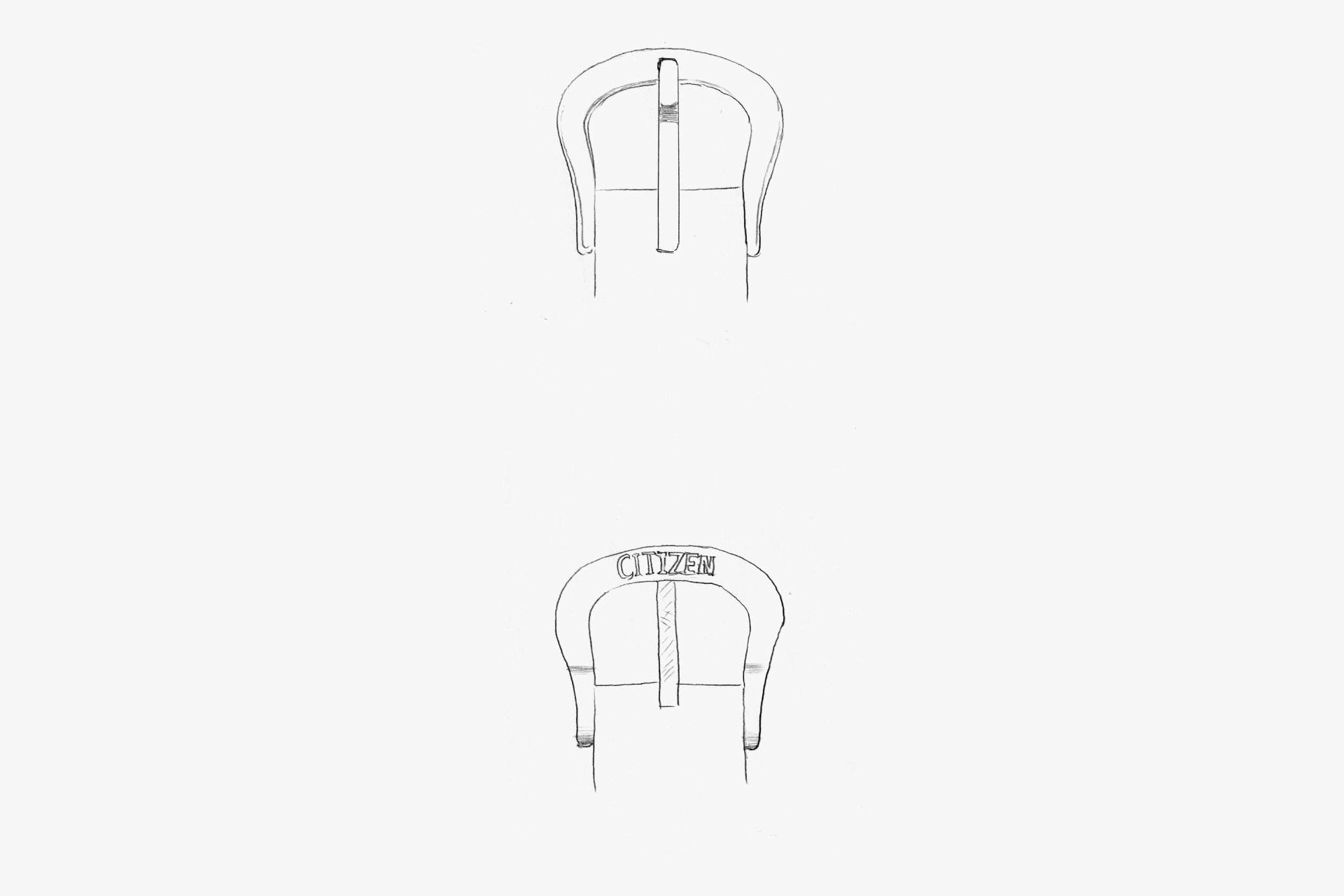

The logo is discreetly engraved on the back of the buckle.

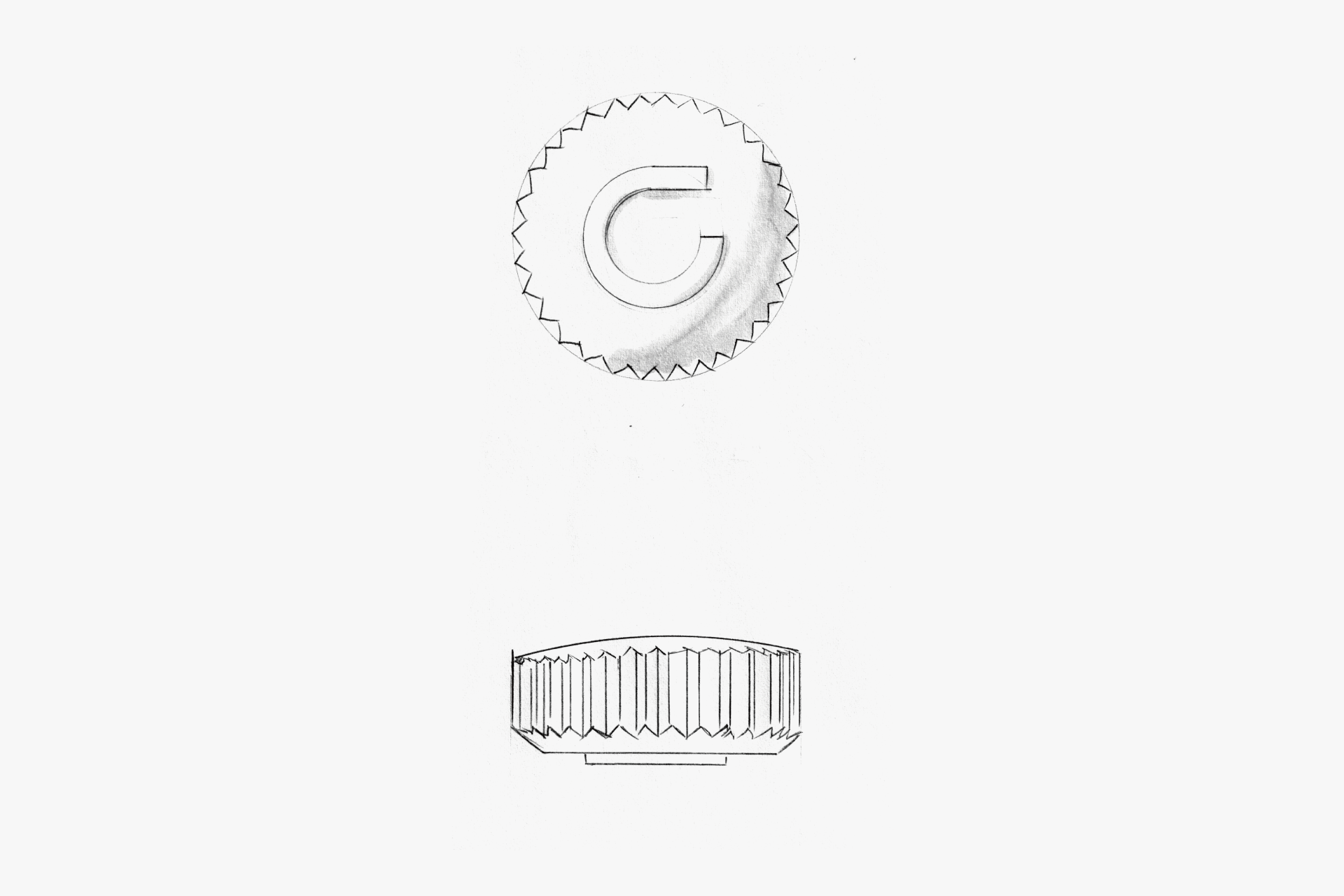

The crown with the C mark provides a sense of reassurance.

The symbolic three stars.

A highly legible dial and the symbolic three stars, achieved through skillful use of space.

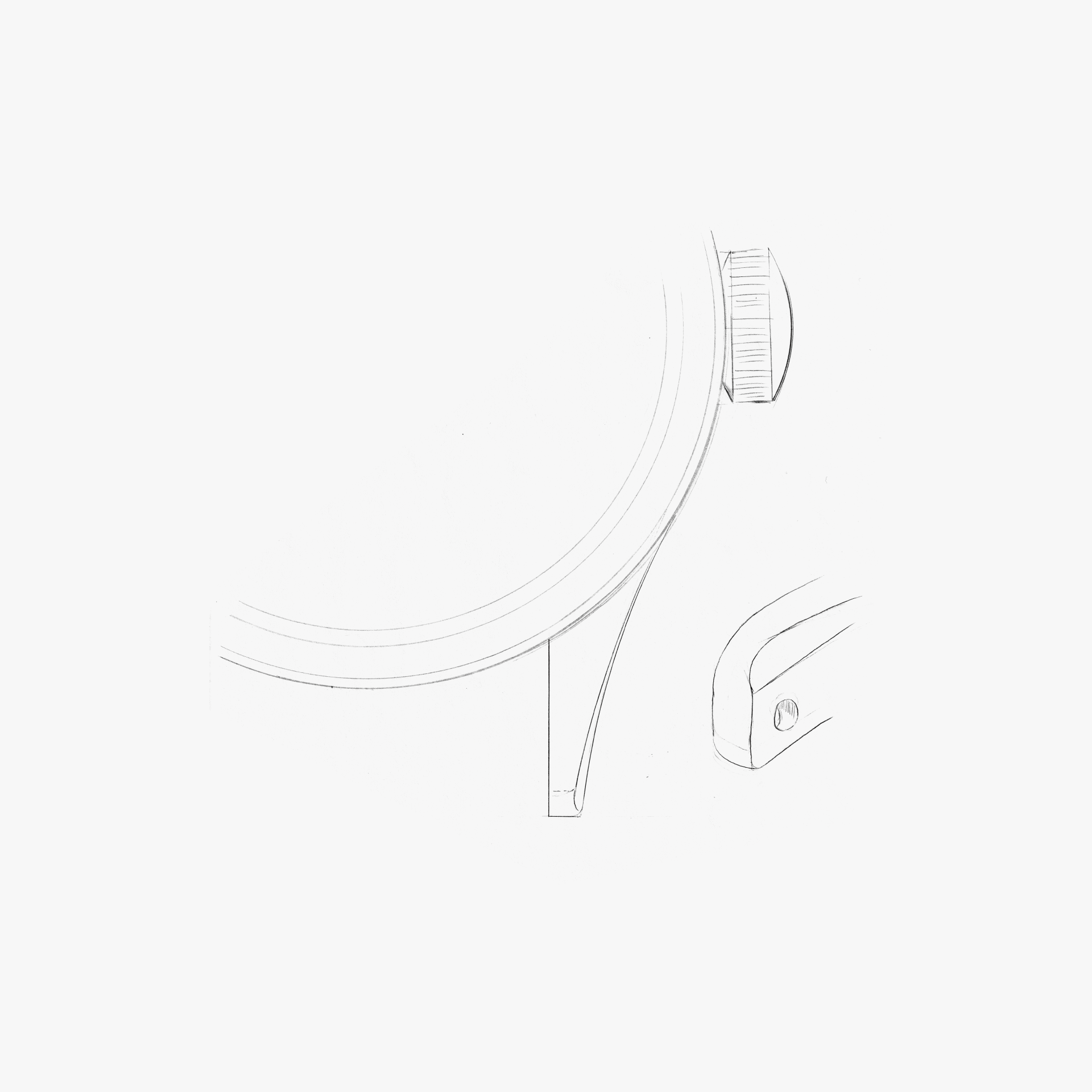

The beautiful ridge at the tip of the lug, which also serves as an accent.

ENGINEER'S EYE

Enhance the Technology

It is no exaggeration to say that the factors behind CITIZEN’s postwar growth in both quality and volume lay in improving the precision of the parts and achieving near-complete interchangeability of components. Once the precision of the parts is ensured, it becomes possible for skilled technicians to perform special adjustments on high‑grade calibers for the first time. And with component interchangeability secured, mass production also becomes feasible.

Precisely machining the positions and diameters of the various holes—so‑called “assorted holes” in the main plate and bridges known as the ébauche, that is, the holes into which jewels and pins are sub‑assembled—is indispensable for ensuring a watch’s performance. In the 1950s, CITIZEN made large‑scale investments, strengthened its tooling department, and mastered pressing technology for “finish punching” these assorted holes. This technology was first deployed in the manufacture of women’s watch movements because, assuming the same machining precision, smaller movements are more susceptible to performance being affected by variations in parts. The Super Queen is a rare specially adjusted model among CITIZEN’s women’s mechanical watches and can be called a gem that demonstrates the advancement of its parts‑manufacturing technology.