This 'Crystron Mega' is a model released in 1976. At the time, there were no highly precise CAD-based cutting machines like we have today, so it is easy to imagine that the skills of many experienced craftsmen were essential in the production of exterior parts.

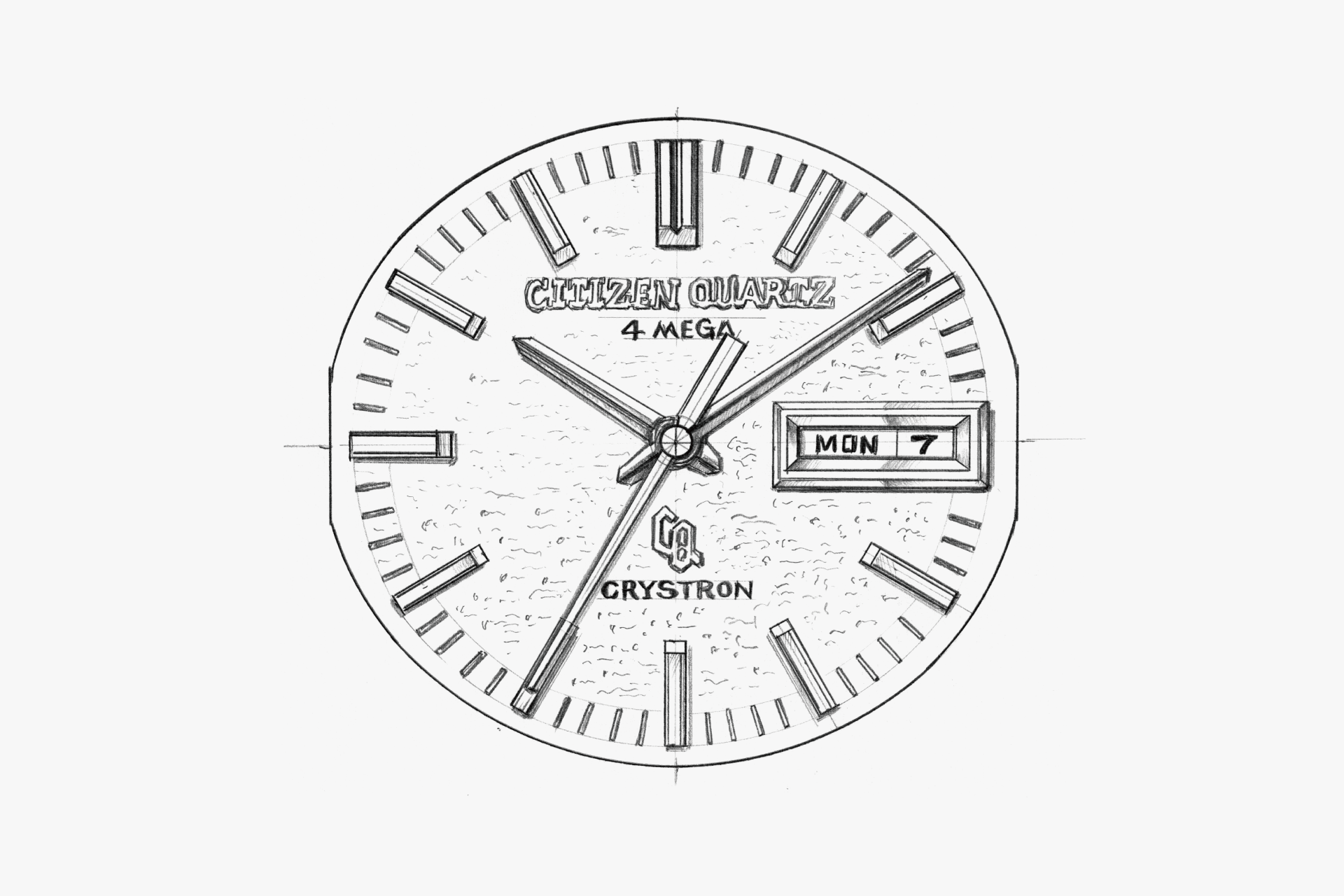

Upon closely examining the shape and each part of this watch, you can see that even the smallest components are meticulously processed and finished. Even the indexes, for example, have tiny steps that require high machining precision and feature 'black printing' likely added to improve legibility—there is no sense of compromise anywhere.

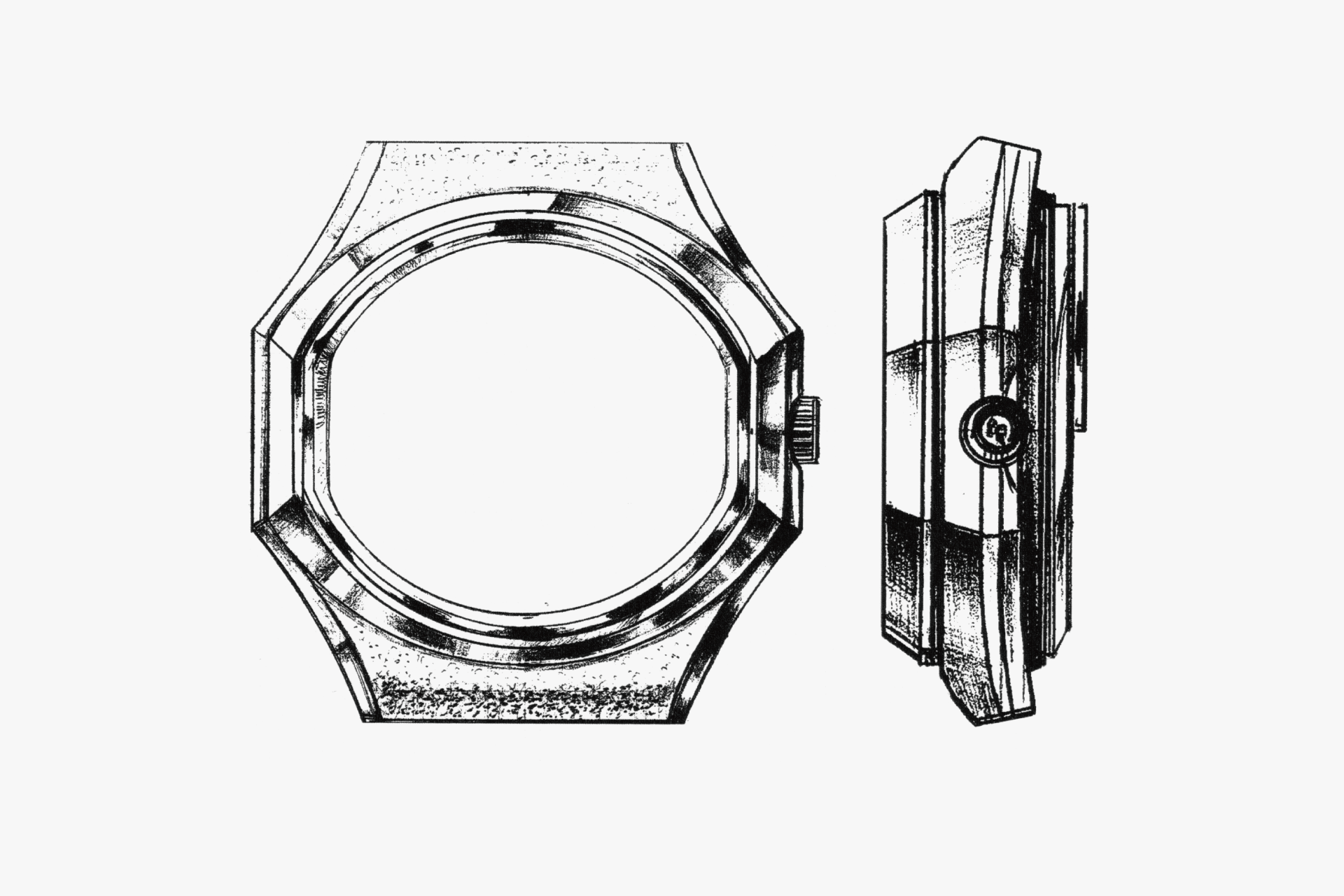

Looking closely at the case shape, you can see bold curves in some areas and sharp, straight-edged cut surfaces that beautifully accentuate the lines. This suggests that the watch was manufactured with a deep understanding of the 'beauty' created by machining. The top surfaces of the case lugs and dial are decorated with sand-blast-like patterns made using metal molds, making the stainless steel surface look lively. It's as if the pattern is calling out, 'Look at me! Look at me!'

The unique TV-shaped design, unlike the typical round watch, gives it a distinctive character. The fine sand-blast finish on the upper surface of the case, which looks like thin lines, also strongly expresses its individuality.

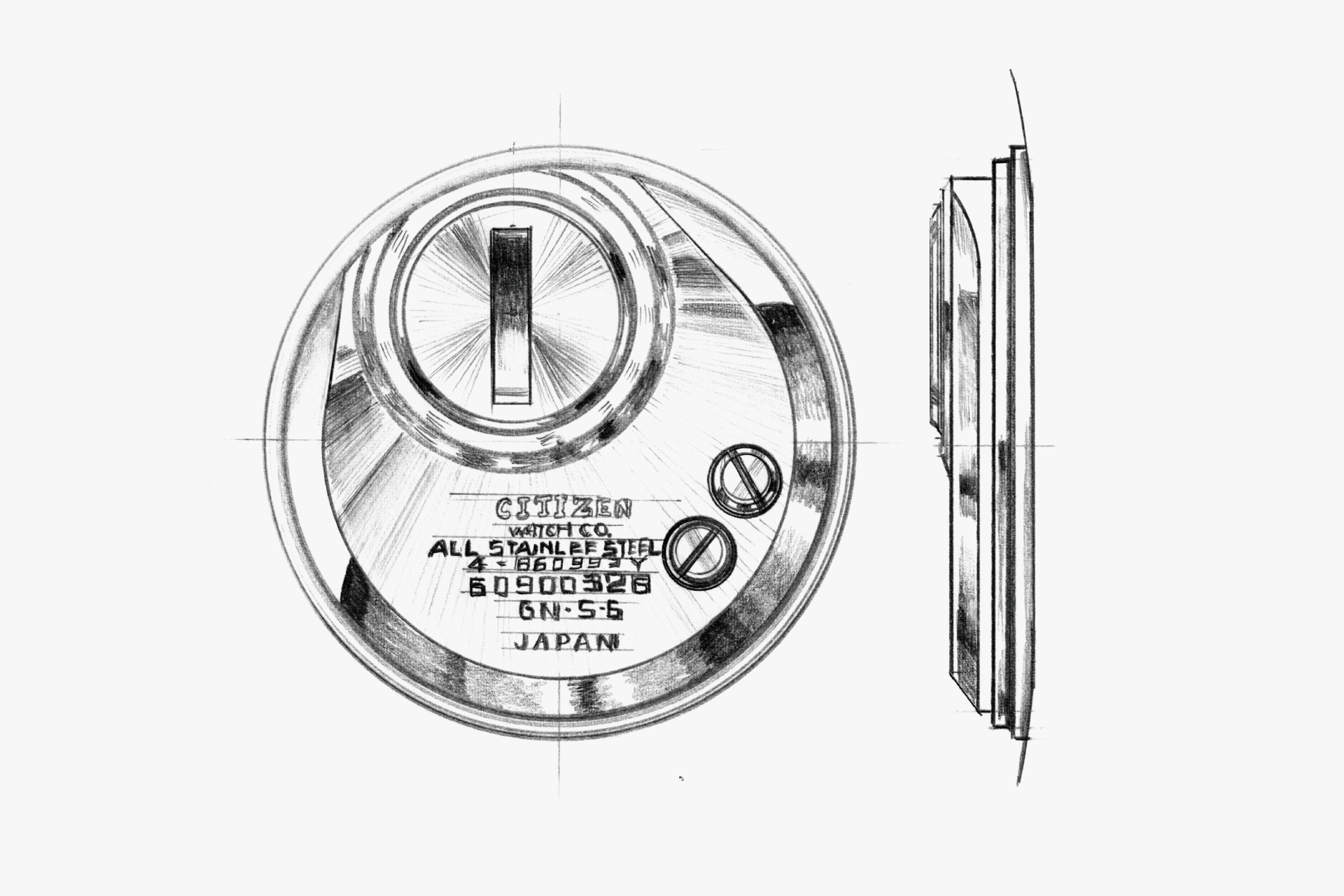

The side profile of the case has a sense of recesses and protrusions that cannot be imagined from the front view. The presence of a battery case back for a small battery on the case back gives it a sharp accent.

The uniquely shaped case, characteristic of its era, features superbly finished edges. The special sand-blast finish on the case surface is also distinctive.

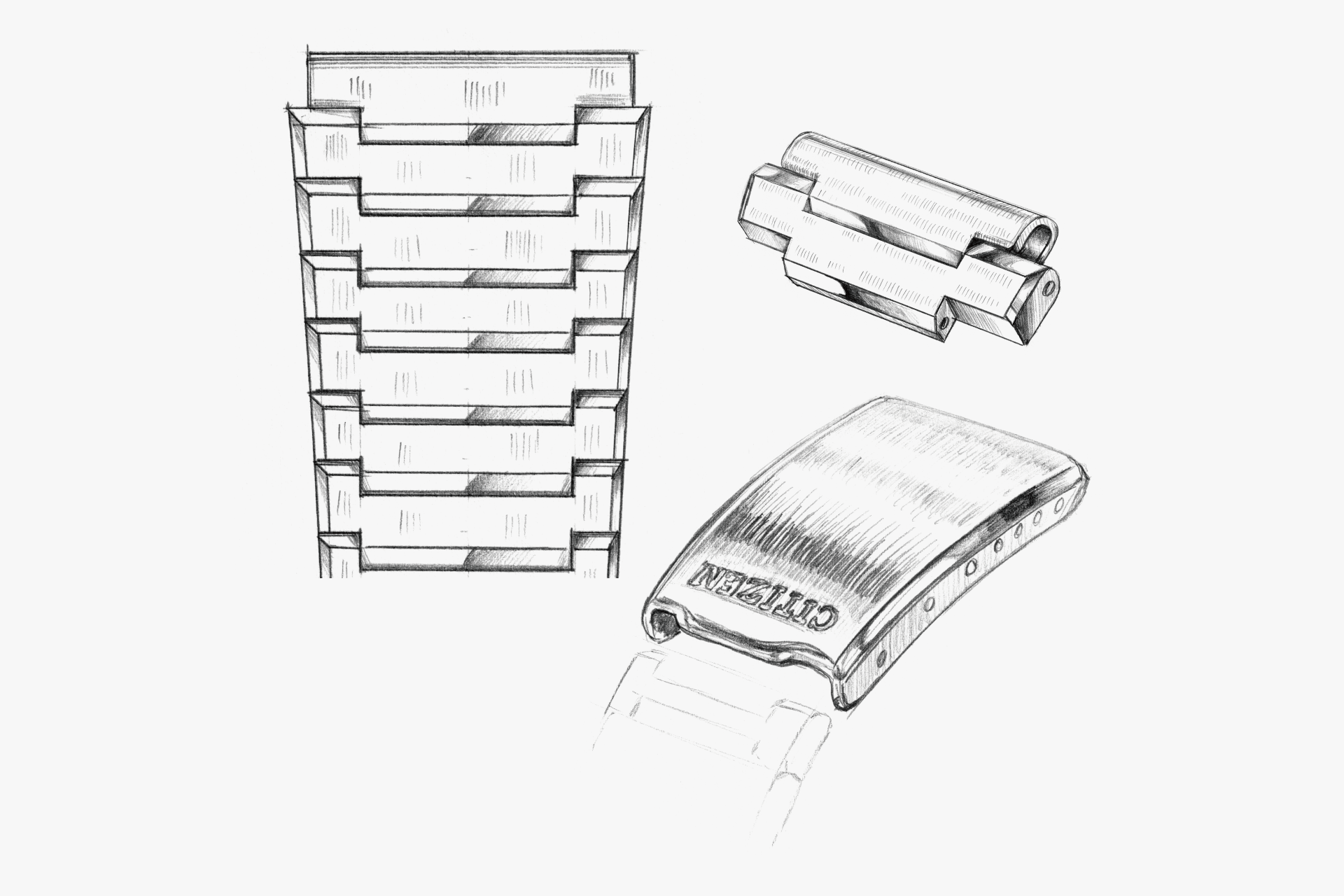

The surface precision of the machining is reminiscent of a Japanese sword. The polished slopes are beautiful, and the sloped surfaces that surround the band convey a sense of the pursuit of beauty.

The case back has a raised feel reminiscent of a steam locomotive, giving it a distinctive shape typical of the time. The center of the sunray pattern aligns with the center of the battery case back.

The real appeal of this watch lies in its three-dimensional presence. Depending on the viewing angle, the watch reveals various expressions and shapes. It has a strong individuality that cannot be achieved with a round shape. The sloped and curved surfaces in each part also showcase the high precision of the machining.

The dial features a distinctive track shape rarely seen today. The rough sand-blast-like texture on the surface is beautifully executed. The machining of the applied indexes is also well done.

The deeply molded 'CQ' mark, created by a mold, is very sharp. The surface finish is also extremely beautiful.

ENGINEER'S EYE

Dawn of Precision Quartz

By adopting a high-frequency 4 MHz (4,194,304 Hz) AT-cut quartz resonator instead of the commonly used 32 kHz (32,768 Hz) tuning-fork type quartz resonator in quartz watches, this model achieved the world’s first annual accuracy within ±3 seconds. Its literally orders-of-magnitude higher oscillation enabled ultra-high precision.

To solve the power consumption issue, which is in a trade-off relationship with oscillation frequency, a newly designed CMOS IC was co-developed with a major U.S. electronics manufacturer. The SOS (Silicon On Sapphire) technology, which employed a sapphire substrate and was cutting-edge at the time, was adopted, delivering an unprecedented reduction in power consumption for that era. As a result, despite using a high-frequency quartz resonator, the watch was completed as a practical timepiece.

The quartz resonator was developed at the CITIZEN Technical Research Institute. At the time, there was nothing this small among AT-cut quartz resonators; it is considered the smallest size in the world.

The technologies cultivated in this watch, accumulated over a long period, have led to Cal. 0100, the world’s first autonomous, light-powered watch with an annual accuracy of ±1 second.