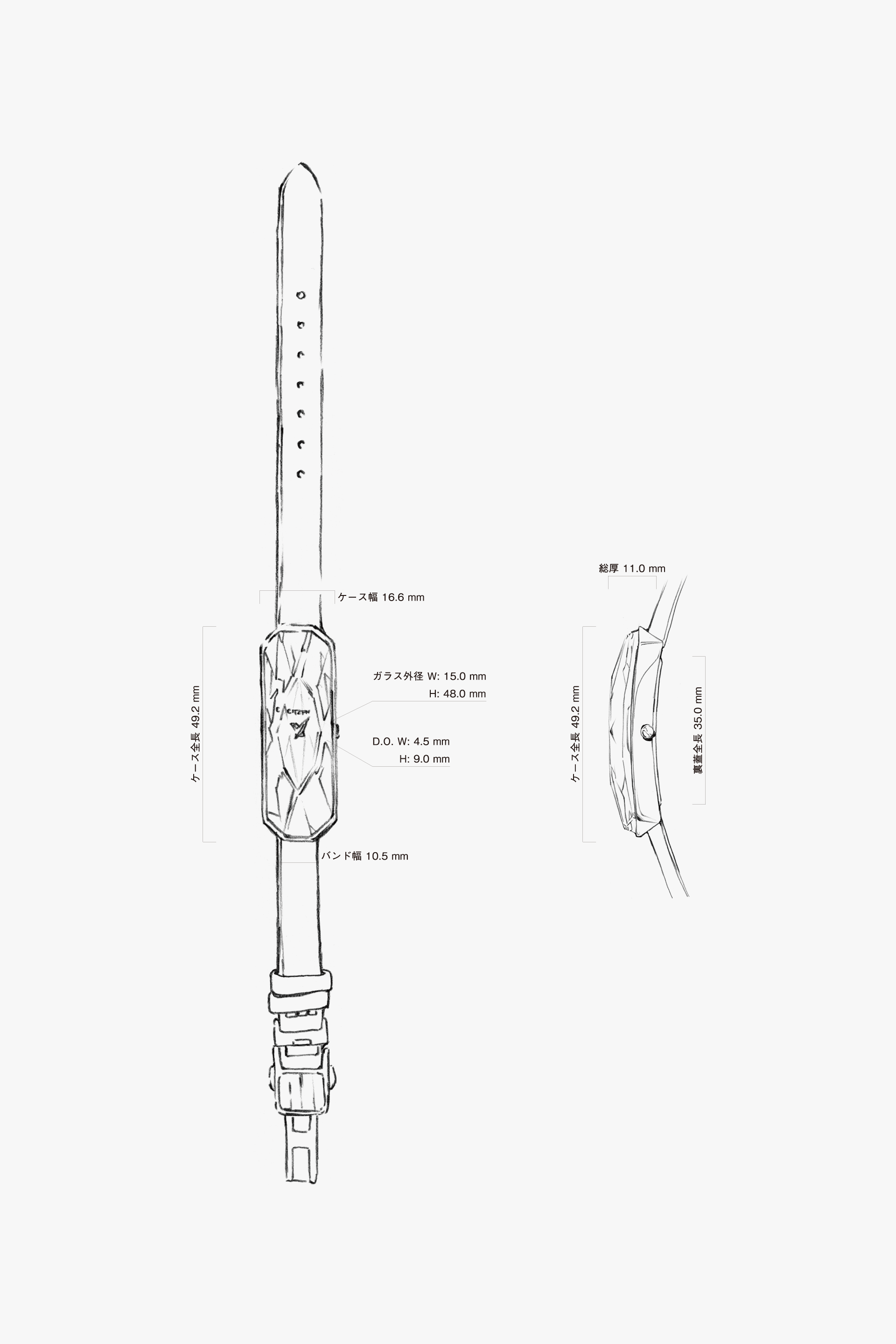

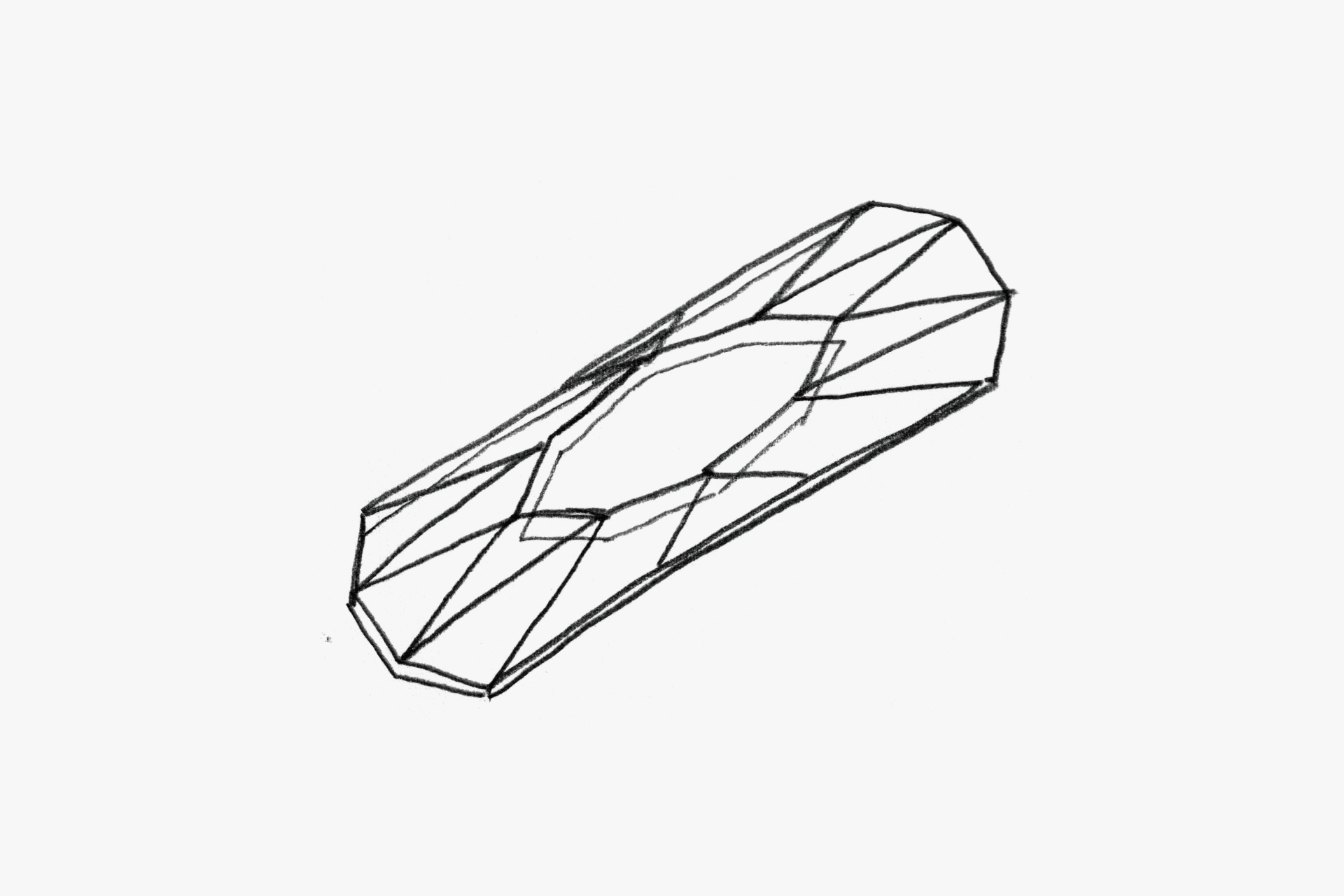

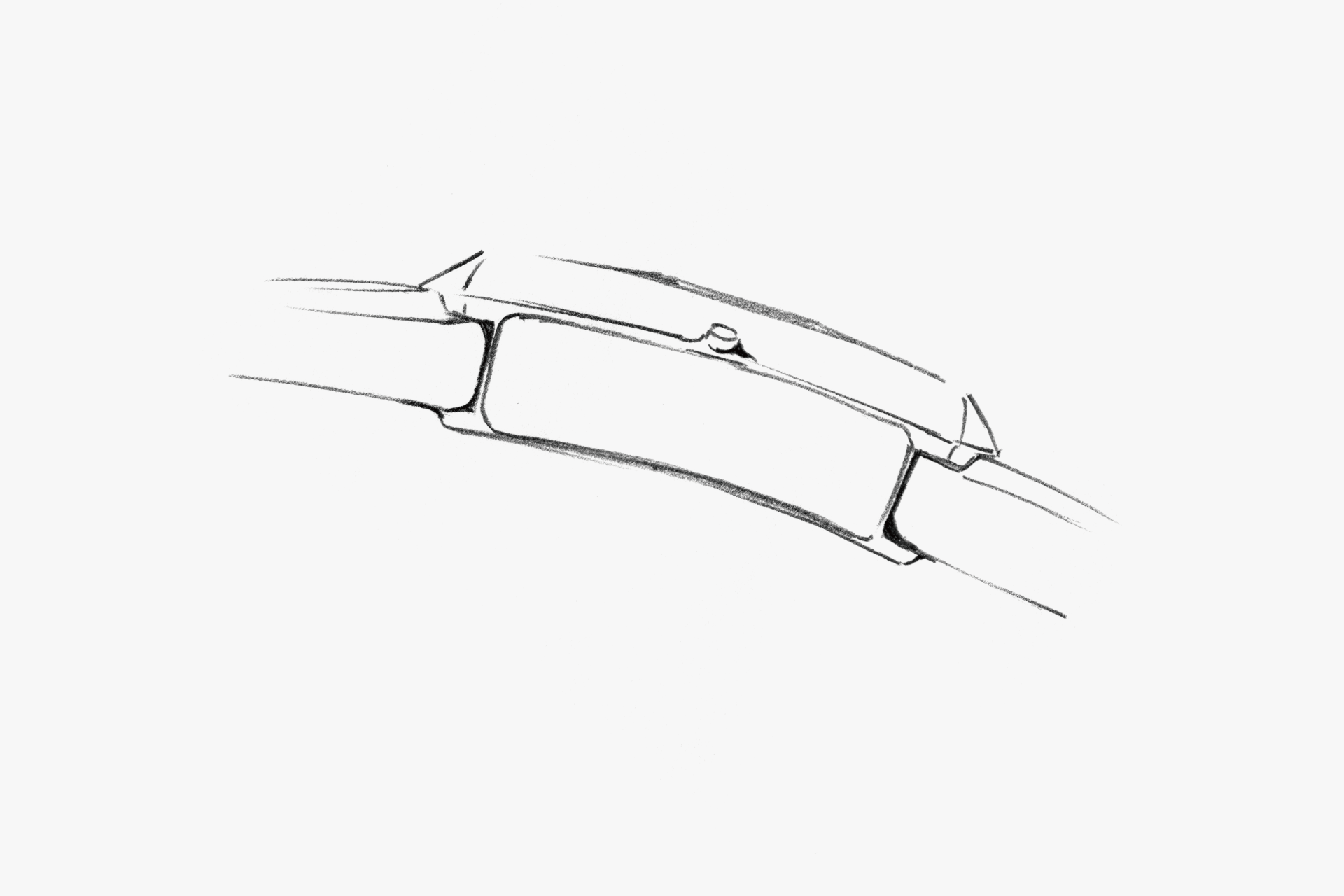

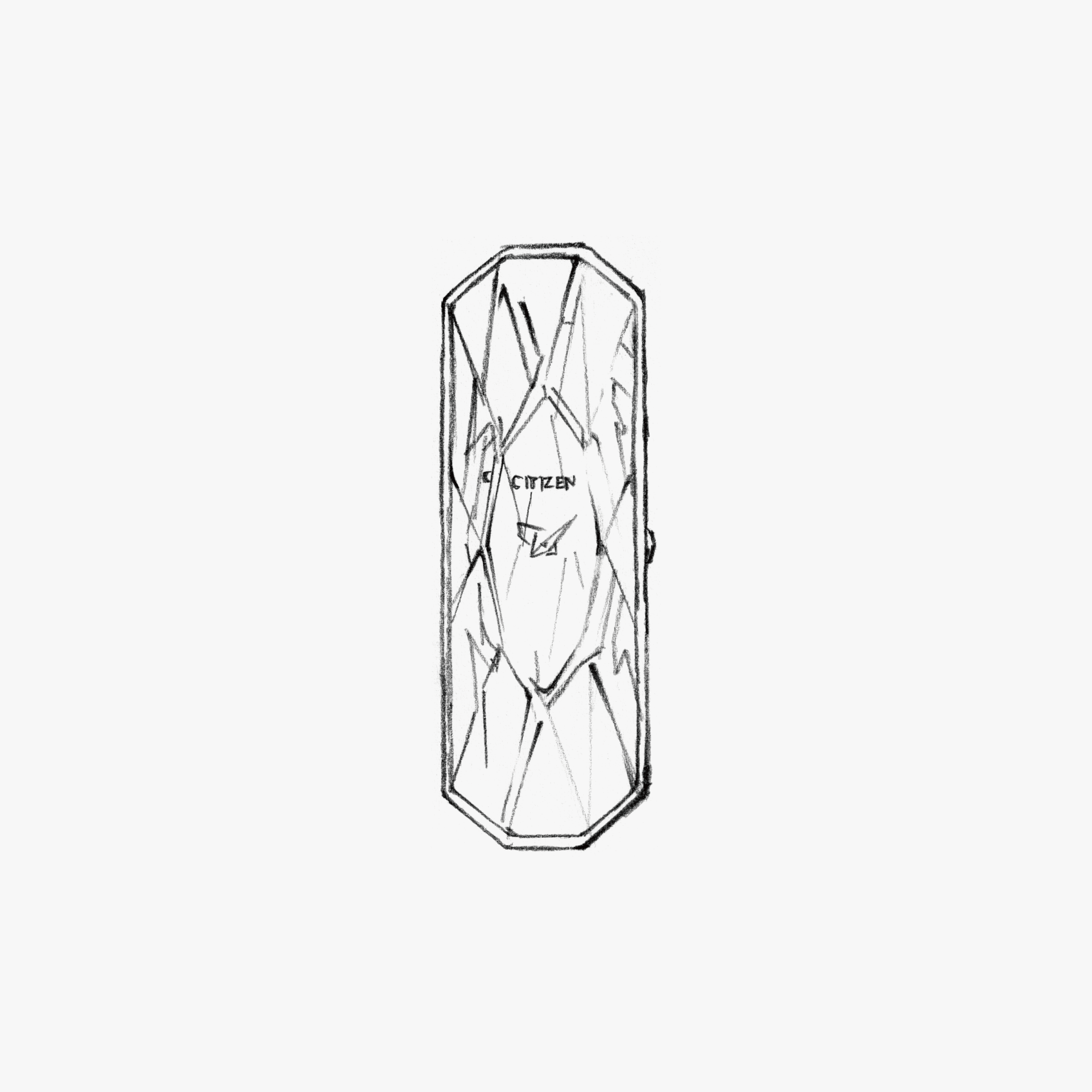

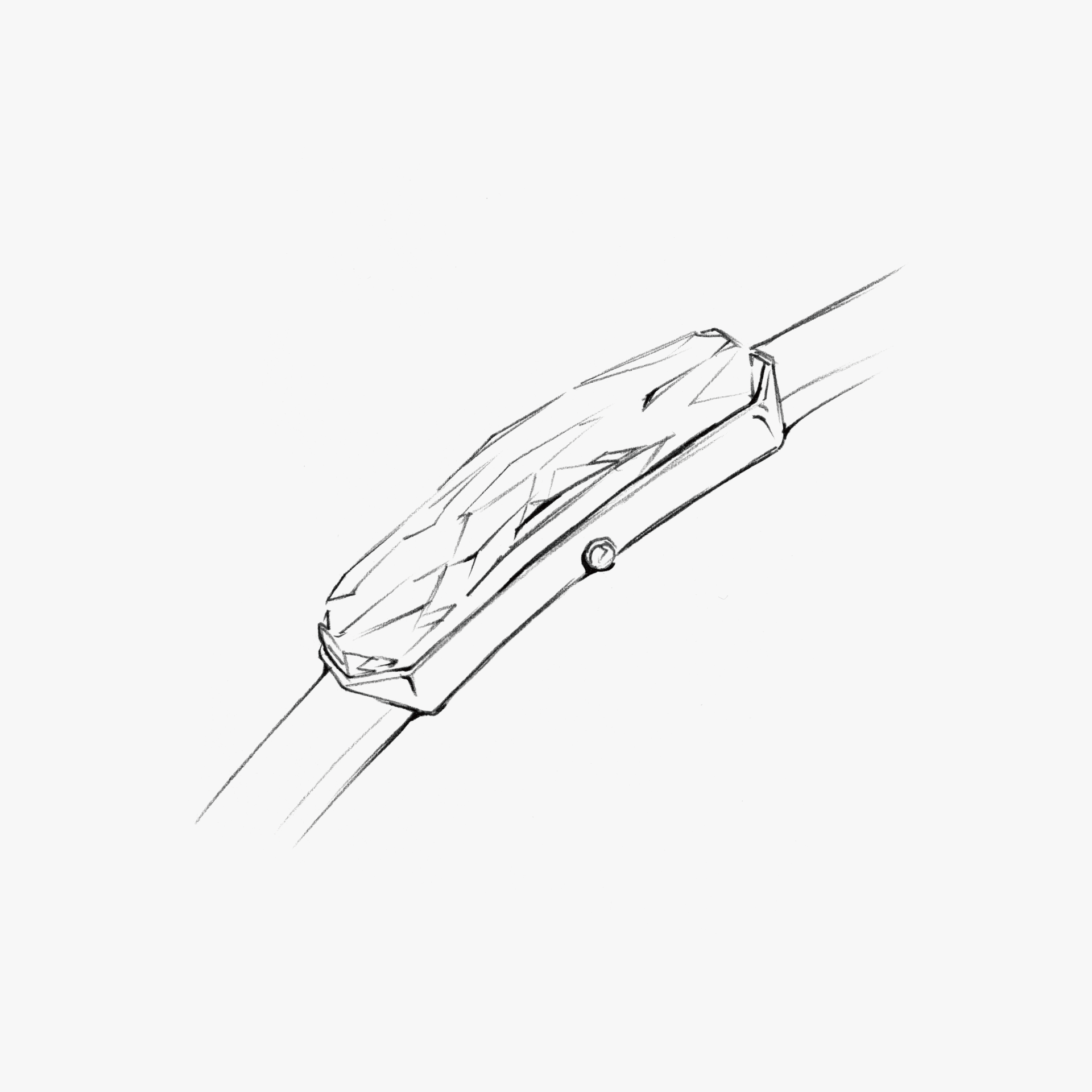

At first glance, you might be tempted to answer "Is it a watch or a jewel?" with the latter, as this model completely breaks away from the conventional appearance of a watch. The bold design fully embodies the concept of "wearing light." The crown is made extremely small, the case is chamfered, and even the clasp is boldly adorned with sapphire, thoroughly expressing the concept. The dial is minimized to the limit without losing balance, fitted with hands inspired by crystals, and the finishing touch is a glass thicker than the center of the case, giving the side profile an impressive presence. Unconstrained by the boundaries of wristwatches, its pursuit of beauty is exhilarating.

A design that, at a glance, doesn't even look like a watch. You'll be captivated by the shifting play of light.

You can see the scenery beyond through it.

Copper coating is applied along the line that drops the ridge of the upper cut to the lower surface. As the light changes, the hue shifts as well, adding depth to the transformation.

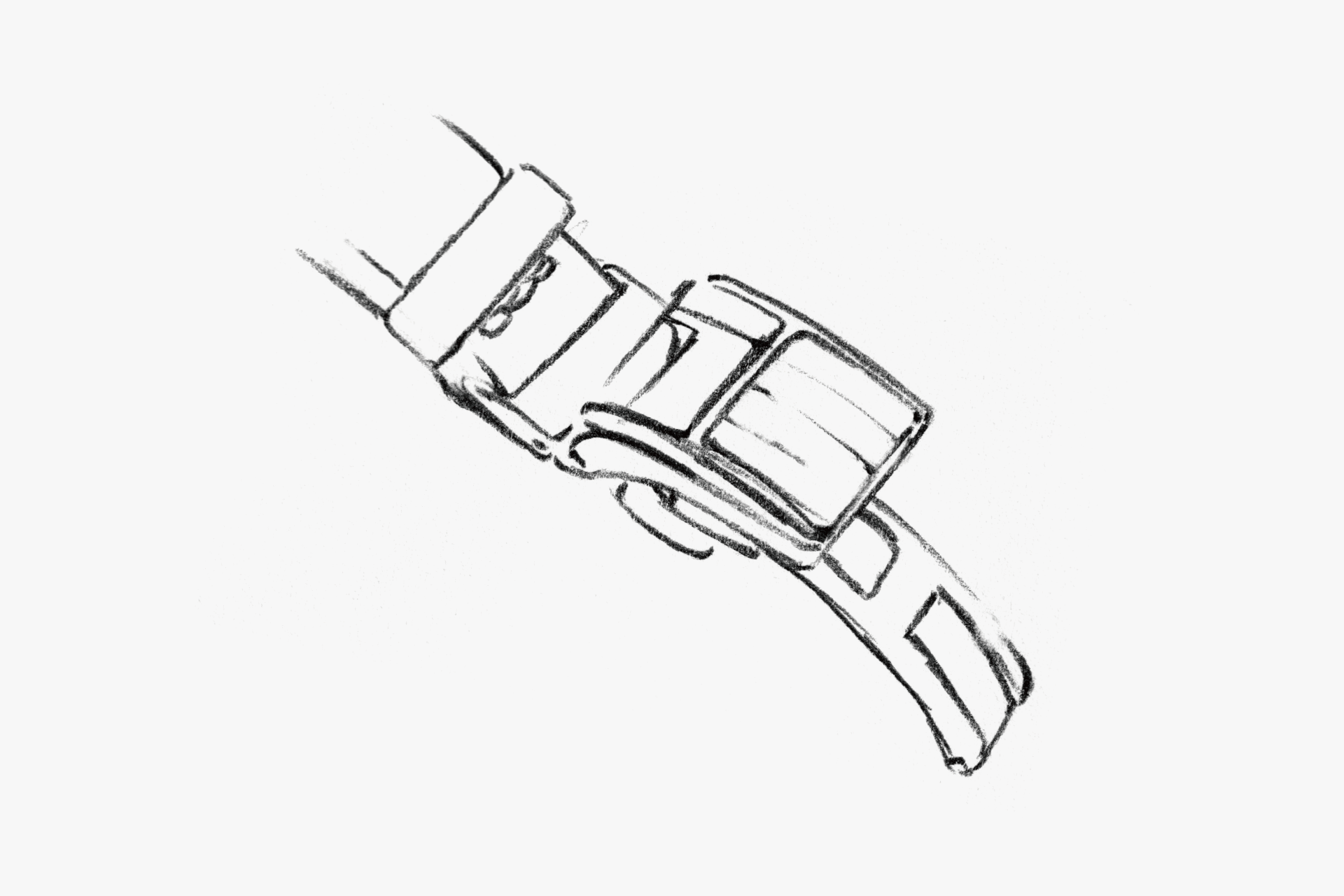

Sapphire is also used in the clasp, and light flows continuously across the four aligned surfaces. It even resembles nail art.

The gentle curve achieves both a sense of edge and comfortable wear.

A case that enhances the beauty of sapphire. The center has a subdued glow, amplifying the vividness and brilliance of the glass.

A dignified brilliance. Though light, sometimes you can see multiple reflections passing through the glass, giving it a rich expression.

ENGINEER'S EYE

The Brilliance at the End of Hardships

The development of this model began with securing sapphire ingots free of impurities. If the ingots are merely large, not only do they pose aesthetic concerns, but they also tend to cause micro-chipping and cracks—known as chipping—during the cutting process, preventing the production of acceptable pieces. After repeated negotiations with ingot manufacturers, and with an amount of time that felt endless and the utmost care in manufacturing, we somehow managed to secure the necessary quantity.

Next came the polishing of this large, extremely challenging multi-faceted cut. We tried machine polishing, but the quality fell far short of satisfactory, and we ultimately turned to a Japanese master renowned for sapphire glass polishing. As mentioned earlier, sapphire ingots for watches are produced over a long period of time; during that process the sapphire crystal develops anisotropy, and the polishing needs to be adjusted each time to align with this orientation. Even the slightest misjudgment in pressure can cause chipping or throw the ridgelines out of alignment, rendering unshippable even pieces that have been cut into dozens of facets. This seemingly impossible and arduous task was accomplished thanks to the cooperation of a single master, giving birth to this Collection Saphir.

It is a radiant bracelet watch equipped with what was then the world’s smallest Eco-Drive movement.